【Product description】: Rotary kiln refers to rotary calcining kiln, widely used in building materials, metallurgy, chemical industry, environmental protection and other industries.

【Product capacity】: 300-3000 t/d

【Product application】: Cement Plant, Steel Mill, Chemical Plant & Incinerator

1. Rotary kiln has many advantages, such as great production capacity, high mechanization and automation, strong adaptability to raw material, high activity of its product, stable production operation, perfect environmental protection measures, etc.

2. The rotary kiln has simple structure, and the kiln body is mainly composed of cylinder, bearing, drive, sealing device for kiln head and kiln tail. It has convenient and reliable production process control, less quick-wear parts and high operation rate. It is equipment for cement plants to calcine cement clinker.

3. It is easy to operate and its performance is reliable. The thermal regulation being stabilized and the operation rate being improved, compared with equipment with the same specifications, the operation rate increases by 10%, yield by 5%-10%, heat rate reduces by 15%.

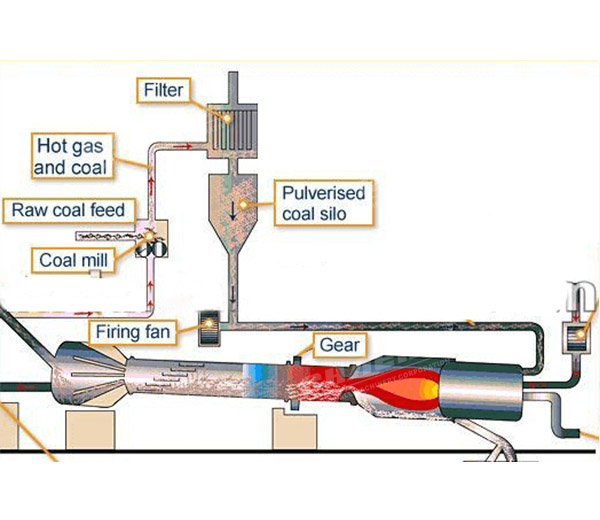

The rotary kiln is a cylindrical vessel, inclined slightly to the horizontal. The material is fed into the upper end of the cylinder. As the kiln rotates, the materials gradually move towards the lower end, and they may go a certain amount of stirring and mixing. Hot gases go through the rotary kiln, in the same direction as the process material, but usually in the opposite direction. The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. They are repetitively scattered in the air so that they are in full contact with the hot air, the material is dried gradually.

| Model(m) | Output(t/d) | Main Drive(r/min) | Motor model | Rated power(kw) | Regulating Range(r/min) | Rated Voltage(v) | Gearbox | DeceleratorVelocity Ratio | Total Weight(t) |

|---|---|---|---|---|---|---|---|---|---|

| Φ2.2×50 | 96 | 0.125-1.25 | YCT280-4A | 30 | 132-1320 | 380 | ZS145-11 | 157 | 130.71 |

| Φ2.5×50 | 130 | 0.516-1.549 | YCT355-4A | 55 | 440-1320 | 380 | ZS165-7 | 99.96 | 167.5 |

| Φ3×48 | 850 | 0.3309-3.309 | ZSN4-250-21B | 90 | 100-1000 | 440 | ZS130-14 | 32.11 | 237 |

| Φ3.2×48 | 1000 | 0.375-3.75 | ZSN4-280-21B | 160 | 100-1000 | 440 | NZS1240-28 | 27.469 | 252 |

| Φ3.2×50 | 1200 | 0.398-3.975 | ZSN4-280-11B | 190 | 150-1500 | 440 | ZL130-16 | 40.85 | 263 |

| Φ3.3×52 | 1200 | 0.391-3.91 | ZSN4-355-082 | 190 | 100-1000 | 440 | ZSY500-28 | 27.707 | 280.8 |

| Φ4×60 | 2500 | 0.396-3.96 | ZSN4-355-092 | 315 | 100-1000 | 440 | ZSY630-35.5 | 34.601 | 487.5 |

| Φ4.2×60 | 2800 | 0.4165-4.165 | ZSN4-355-12 | 420 | 100-1000 | 440 | ZSY710-35.5 | 35.526 | 576.1 |

| Φ4.3×62 | 3000 | 0.398-3.98 | ZSN4-355-12 | 420 | 100-1000 | 440 | ZSY710-35.5 | 35.714 | 598.5 |

| Φ4.3×64 | 3200 | 0.449~4.49 | ZSN4-355-12 | 450 | 100~1000 | 440 | JH630C-SW305-25 | 24.365 | 585 |

| Φ4.5×66 | 4000 | 0.41~4.1 | ZSN4-400-22 | 630 | 100~1000 | 660 | JH800C-SW306-35.5 | 34.069 | 710.4 |

| Φ4.8×70 | 5000~5500 | 0.4~4.0 | ZSN4-400-22 | 630 | 100-1000 | 660 | JH800C-SW306-31.5 | 30.876 | 845.3 |

| Φ4.8×72 | 5000 | 0.403~4.03 | ZSN4-400-22 | 560 | 100~1000 | 660 | YNS1760-31.5VDR | 30.365 | 847 |

| Φ4.8×74 | 5000 | 0.35~4 | ZSN4-400-092 | 630 | 130~1500 | 660 | JH710C-SW305-40 | 42.226 | 841 |

Kenya's 3.2*48m cement rotary kiln, the customer highly recognized the product quality of Xinxiang Great Wall Machinery

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China