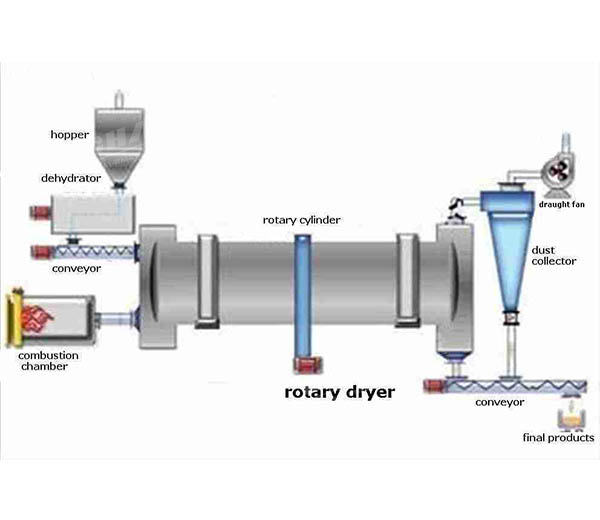

【Product description】: The dryer is mainly used for drying materials of certain humidity or particle size such as slag, coal mud and de-sulfurized gypsum.

【Product capacity】: 13-80 t/h

【Product application】: Cement, chemical industry, metallurgy, building materials and other fields;

1.Adopt downstream drying methods

2. Strong overload resistance It has big capacity, low fuel consumption and drying cost.

3. It can change operating parameter according to different materials, which makes that dryer can form stable cascade

4. New type inner structure enhances the clearance of scattered materials and heat transferring process, which removes pasting phenomenon of inner barrel and has high adaption for materials and stickness.

5. Control the granularity and water of product according to the need of our customers, which makes that the moisture can be up to 8%, and particle can control lower than 8%.

The fourth generation of the dryer developed by CHAENG adopts high &low temperature drying patent technology, which fundamentally solves the disadvantage of the former dryer. It has the advantages of intelligent fire-proof, reliable fire handling equipment, no any resistance in material discharging channel, multi-channel material discharging, uniform discharging, low crushing rate, and stable drying quality, and has been applied on all kinds of cement plant and chemical plant.

| Specification (m) | Cylinder Volume (m³) | Capacity (t/h) | Installation pitch (%) | Max inlet Temperature (℃) | Main Motor (kw) | Total Weight (t) |

|---|---|---|---|---|---|---|

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

The dryer of CHAENG has been successfully applied in intelligent semi-coke drying project of Inner Monggol Bai Yanhu Chemical Co., LTD. The project is completed on November 16, 2013, and tested successfully one-time. Original moisture of semi-coke is 20%, final moisture after drying is 1%, crushing rate is 2%, and capacity > 15 tons/h. All the indicators meet the design requirements completely.

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China