【Product description】: CHAENG rod mill is suitable for coarse ore grinding, can be used as the first-stage grinding.

【Output】: 30--250t/h

【Finished product fineness】: 0.833-0.147mm

【Power】: 75~1400kW

【Processing materials】: Cement, ore, slag, steel slag, etc.

1.Energy saving

2. Good discharged particle size

3. Good at wet grinding

4. Easy installation and easy access

5. Wet overflow discharging design

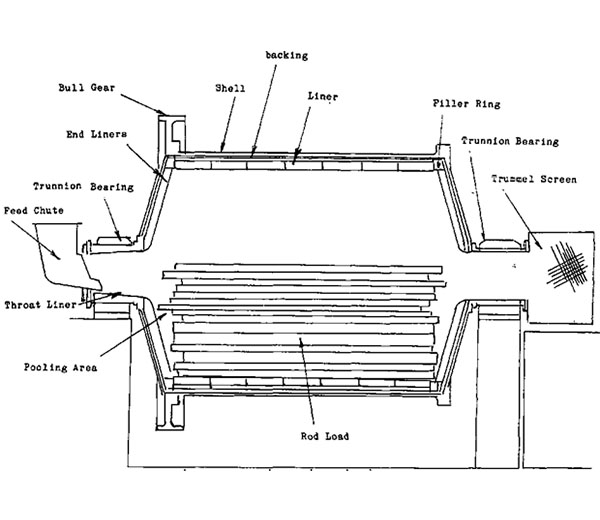

During the work of rod mill, the motor drives through the reducer, driving the cylinder to rotate. The grinding media-steel bars in the cylinder body. Under the centrifugal force and friction force, grinding media will be elevated to a certain height, and then fell in purging fall state. The material to be milled and they will be fed continuously into the cylinder from the feeding mouth; they are crushed by the mobile shattered grinding media, and then discharged finished material through the overflow and continuous feeding power, for the next work step.

| Model (m) | Diameter (mm) | Lengtd (mm) | Effective Volume (m³) | Rotation Speed (r/min) | Grinding Medium Load (t) | Power (kW) | Weight (t) | Remark |

|---|---|---|---|---|---|---|---|---|

| Φ1.5×3 | 1500 | 3000 | 5 | 23 | 8 | 75 | 20 | |

| Φ3.1×3 | 2100 | 3000 | 8.8 | 19.4 | 25 | 220 | 48 | |

| Φ3.4×3 | 2400 | 3000 | 11.8 | 18.2 | 27 | 250 | 58 | |

| Φ2.7×3.6 | 2700 | 3600 | 18.8 | 17.5 | 42 | 400 | 70 | |

| Φ3.0×4 | 3000 | 4000 | 25.9 | 16.2 | 50 | 500 | 89 | |

| Φ3.2×4.5 | 3200 | 4500 | 33 | 15.5 | 56 | 630 | 111.5 | Used for tde Coal Water Slurry Mill |

| Φ3.2×4.8 | 3200 | 4800 | 34 | 15.5 | 60 | 710 | 121.2 | |

| Φ3.4×5.8 | 3400 | 5800 | 49 | 14.65 | 95 | 900 | 160 | |

| Φ3.6×5.4 | 3600 | 5400 | 50 | 14.5 | 97 | 1000 | 155 | |

| Φ3.6×5.8 | 3600 | 5800 | 53.8 | 14.3 | 135 | 1120 | 175 | |

| Φ3.8×5.2 | 3800 | 5200 | 54.1 | 14.2 | 102 | 1120 | 175 | |

| Φ3.8×5.8 | 3800 | 5800 | 60.3 | 14.2 | 112.2 | 1250 | 156 | Rubber Liner |

| Φ4.0×6 | 4000 | 6000 | 70 | 14 | 130 | 1400 | 163 | Rubber Liner |

Rod mill 30t/d required by customers in Kazakhstan, play extremely good production performance.

E-mail: [email protected]

Tel.:+8615290747879

WhatsApp:+8615290747879

![]() Wechat:+8615290747879

Wechat:+8615290747879

Office Add: Mengzhuang Town, Huixian City, Henan Province, China