14 Sep,2015 UTC+8 Views:

The use of GGBS (GGBFS):

Two major uses of GGBS (GGBFS) are in the production of quality-improved slag cement, namely Portland Blast furnace cement (PBFC) and high-slag blast-furnace cement (HSBFC), with GGBS content ranging typically from 30 to 70%; and in the production of ready-mixed or site-batched durable concrete. Use of GGBS (GGBFS) significantly reduces the risk of damages caused by alkali–silica reaction (ASR), provides higher resistance to chloride ingress-reducing the risk of reinforcement corrosion — and provides higher resistance to attacks by sulfate and other chemicals.

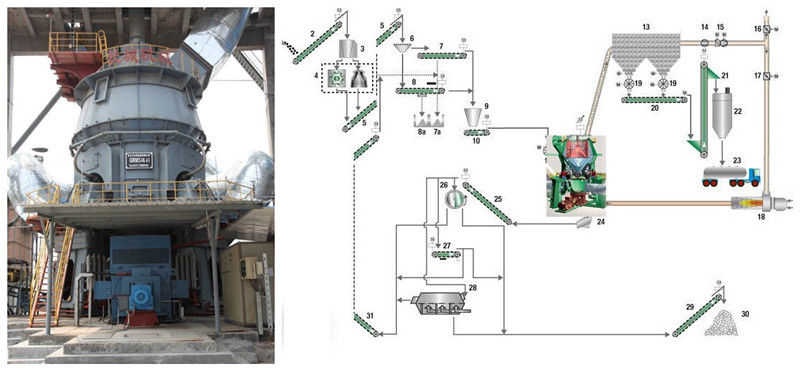

GGBS (GGBFS) powder vertical roller mill equipment: the specific furnace area of the finished products can be freely adjusted between 4200-4500cm2/g, and the capacity (ton/hour) ranges from 50T/H to 180T/H depending on the final size and the grinding materials.

Main Components of GGBS (GGBFS) powder production line equipment: GRMS series GGBS (GGBFS) powder vertical roller mill equipment mainly consist of main unit, classifier, dust cleaner, powder collector, blower, muffler, hammer crusher (can be replaced by jaw crusher), bucket elevator, sound-proof room, storage hopper, vibrating feeder and so on.

Working Principle of GGBS (GGBFS) powder production line equipment:

The main bearing and each dial are driven by electromotor of main machine through reducer, and numbers of rollers, which are rolling in the ring, are driven by dial through plunger. After crushed by hammer crusher, the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the electromagnetic vibrating feeder and feeding pipe. The materials will be driven to the edge of dial by centrifugal force and fall down into the ring, crushed and grinded by roller, and become powder after production of three rings. The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier. The rotating turbo in the powder concentrator will make the coarse powder return to the mill and reground, while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin, which is at the bottom of it. The air, which mixed with very little fineness, will be purified by impulse duster and discharged by blower and muffler.

Technical data of GGBS (GGBFS) powder GRMS vertical roller mill:

|

Specification |

Diameter of Millstone |

Diameter of Roller |

Quantity of Roller |

Installed Power |

Capacity |

|

mm |

mm |

n |

kw |

t/h |

|

|

GRMS33.31 |

3200 |

1700 |

3 |

1600 |

50 |

|

GRMS35.41 |

3500 |

1800 |

4 |

1800 |

60 |

|

GRMS40.41 |

4000 |

1900 |

4 |

2240 |

70 |

|

GRMS43.41 |

4300 |

2120 |

4 |

2800 |

90 |

|

GRMS46.41 |

4600 |

2240 |

4 |

3150 |

105 |

|

GRMS48.41 |

4800 |

2240 |

4 |

3550 |

125 |

|

GRMS50.41 |

5000 |

2360 |

4 |

3800 |

140 |

|

GRMS53.41 |

5300 |

2500 |

4 |

4200 |

160 |

|

GRMS56.41 |

5600 |

2500 |

6 |

5000 |

180 |

More information about the ground granularity blast furnace slag production line, pls contact us