05 Aug,2019 UTC+8 Views:

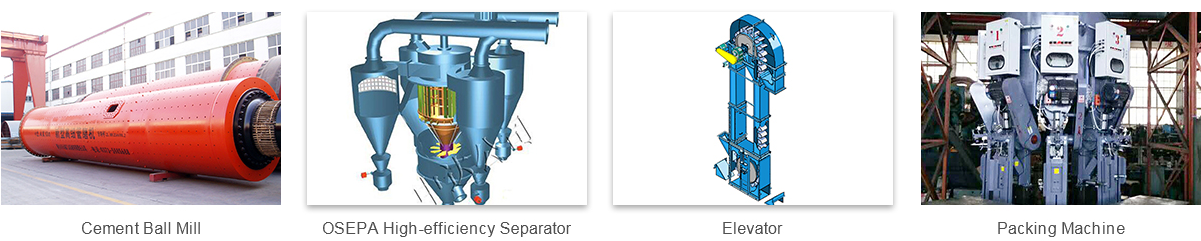

The whole system of cement grinding plant mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement ball mill, OSEPA high-efficiency separator, elevator, packing machine and so on. In order to meet the customers' requirements on different granularity of auxiliary materials, it can be equipped with high-efficiency hammer crusher for optimal combination and classification.

Available Benefits:

1.Less investment, high return

The CHAENG cement grinding station overcomes the of the traditional equipment’s shortcoming that the clinker grinding cost is too high. The system configuration is reasonable, the production efficiency is high, the output is large, and the investment can be recovered in 3 months.

2.Durable equipment, simple operation

The cement grinding station is equipped with a modern electronic control operating system. It has a high degree of automation and simple operation, requiring no manual operation except for the switch machine and routine maintenance.

3.EPC mode, saving purchase costs

CHAENG can provide customers with: ① complete equipment and accessories for cement grinding plant; ② EPC services: complete solutions including design, research and development, manufacturing, transportation, installation, commissioning, training, and after-sales.